Process Technical Safety

The design of any facility must protect human life, prevent pollution and safeguard capital investment for the life cycle of the asset. Health, Safety & Environment (HSE) has become a prime area for management attention in recent decades. Strict, complex national and international regulations apply, posing significant challenges to continuously improve HSE standards and behaviours. HSE performance is not static but requires vigorous attention at all times while executing any industrial activity.

Versatec Energy provides HSE consultancy support, ranging from the drafting of HSE Management Systems and documents to executing ad-hoc studies for multinational operating companies and large-scale projects. We review loss prevention requirements in the design stages – or follow up during later project phases – to pinpoint all potential hazards and incorporate mitigating measures. We advise management and operational staff on compliance with legislation and anticipate upcoming HSE developments.

Examples of our HSE support, studies and reporting services for clients to ensure safe and reliable industrial operations are:

• Safety Management Systems

• Safety & Health Documents (Safety Cases/RoMHs)

• Quantitative Risk Assessments (QRA)

• Risk Acceptance Criteria (RAC), Risk Assessment Matrix (RAM)

• Fire and Explosion Risk Assessments (FERA) using PHAST and SAFETI-NL Software

• Reliability Analyses / Emergency Systems Survivability Assessments (ESSA)

• Ship Collision, Helicopter Transport, Smoke and Gas Ingress studies

• Safety Critical Elements / Safety Critical Activities, Written Scheme of Verification

• Evacuation, Escape and Rescue Assessments (EERPA)

• BowTie, Cause & Effect, SIL, HAZID, HAZOP, RI&E Safety Reviews (as part of our Compliance services)

Contact us at: info@versatec.nl or by phone at +31-348-437460 for more information.

Viewport

Viewport creates a single point of access to all information and significantly improve efficiency, safety, and compliance of you plant or facility.

Viewport – saves time, costs and mitigate risks.

Viewport Risk

Viewport Risk increases the efficiency & completeness of the compliance process (internally & externally). Think of Safety Requirement Specifications (SRS) verification for example.

In combination with the Dynamic BowTie you instantly see the effects of a change in a procedure, P&ID, SOP, or other process critical document in your BowTie and on your barrier management. Changes which have a direct effect without the organization being aware of.

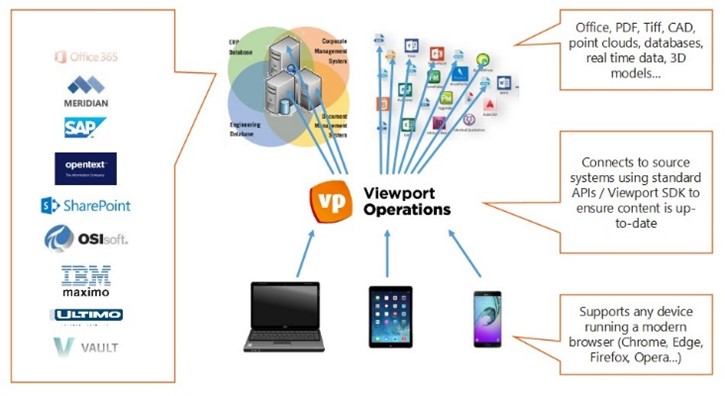

Viewport Operations

Viewport combines your process critical information from various systems into one single point of truth, via advanced analytics, pattern recognition and hyperlinks. As a result, employees have 15-30% more time for their substantive work and always have the correct version of the process-critical documents. So, they can make faster, better decisions, and perform their work first time right. This saves you time and money.

SafeEx

SafeEx Software sets a new standard for inspection and maintenance, offering one software for all inspection and maintenance routines. The focus is on improving safety, increasing efficiency and providing full transparency.

Using RFID technology and handheld devices (certified for zone 1 and 2), SafeEx proves the inspector’s presence on site. SafeEx enables your personnel to electronically register all observations/non-conformities during inspection and creating a full electronic audit trail.

The reduction of manual tasks saves you at least 30% in manhours. This fact alone ensures a return on your investment in less than 1.5 years.

The SafeEx Software has a multi-purpose base, allowing a uniform setup for all units. This gives a full transparency and traceability of all units and can be used for preventive maintenance.

PCCS

The Project Completion Commissioning & Startup (PCCS) method developed ensures that the various activities within a project are done in the correct order. And, more importantly, that the next step is only taken after subsequent steps have been accepted by the responsible person. The PCCS structure also offers the possibility to record the reports and thus determine the entire process.

With the PCCS (first time right) approach, you prevent project deviations, stay within the budget and the project planning.

Turnaround Management Plan

Many companies struggle when organizing a major maintenance campaign, STOP or Turnaround. Resulting in negative effects on duration, scope completion, costs and risking short cuts due to time pressure.

The Versatec Turnaround Management Plan (TMP) is the “best practice” method for Turnaround preparation, execution with mitigation of all threats of the Turnaround process steps.

Using the TMP the Turnaround finishes in time, the scope 100% completed, executed safe and within budget.