Operational Excellence

Examples of our Operational Excellence services:

• Operational Readiness and Assurance

• Shorten Turnaround duration

• Technology replication

• Process optimization

• Offshore/onshore operations management and control through entire project

• Mechanical Completion (MC) survey,

• Commissioning/Decommissioning

• Installation & Hook-up support

• Assigning Subject Matter Experts (SMEs) to the client project team as required

• Startup assistance

• Instructions for activities and facilities

• Maintenance Instructions

• De-manning and optimisation studies

• Project Risk management

Integrated Operating Manual (IOM)

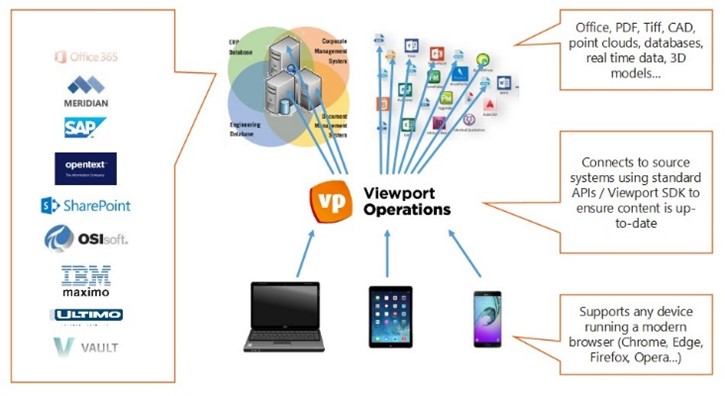

Versatec Energy has teamed up with Radial SG to provide the Viewport™ solution for building an integrated operating manual. Document and data searches for the right brownfield/greenfield asset information now take minutes instead of hours with the instant, intuitive interface and its clickable links. Viewport™ does all the searching, sifting, organising and converting beforehand using smart automated processing. Web-enabled technologies ensure access to data from a wide range of mobile devices, laptops and workstations. In process industry operations this means that everyone can be sure they all are viewing the latest approved (or as built) version of drawings, documents and data.

Intelligent interfacing among manuals, P&ID drawings, vendor data and other source information lets clients expand knowledge across their entire company. The Viewport™ Operations solution is the ideal way to publish and distribute complex technical information for a diverse group of end-users.

Key features include:

- Highlighted, rapid linking technology and multilayered levels of integration to easily extract information stored across different data sources in various disciplines

- Flexible, automatic document cross-referencing to locate tag numbers (or equipment codes), file names and drawing numbers

- Quick Tag Number Search functions linking documents and drawings, with a guideword index for speedy access to specific engineering / operating data

- Easy to use and update (no training needed) and view (Hyperview technology)

Technology Replication and reduction in Turnaround duration

By applying our tools, processes and insights, you can achieve a fast uptake of technology. Specifically for turnarounds, our experience is that the turnaround duration can be reduced by 10% – 100% by applying proven technologies.

We support you to “Plan for success” and “Make it happen”.

Contact us at: info@versatec.nl or by phone at +31-348-437460 for more information

Viewport

Viewport creates a single point of access to all information and significantly improve efficiency, safety, and compliance of you plant or facility.

Viewport – saves time, costs and mitigate risks.

Viewport Risk

Viewport Risk increases the efficiency & completeness of the compliance process (internally & externally). Think of Safety Requirement Specifications (SRS) verification for example.

In combination with the Dynamic BowTie you instantly see the effects of a change in a procedure, P&ID, SOP, or other process critical document in your BowTie and on your barrier management. Changes which have a direct effect without the organization being aware of.

Viewport Operations

Viewport combines your process critical information from various systems into one single point of truth, via advanced analytics, pattern recognition and hyperlinks. As a result, employees have 15-30% more time for their substantive work and always have the correct version of the process-critical documents. So, they can make faster, better decisions, and perform their work first time right. This saves you time and money.

SafeEx

SafeEx Software sets a new standard for inspection and maintenance, offering one software for all inspection and maintenance routines. The focus is on improving safety, increasing efficiency and providing full transparency.

Using RFID technology and handheld devices (certified for zone 1 and 2), SafeEx proves the inspector’s presence on site. SafeEx enables your personnel to electronically register all observations/non-conformities during inspection and creating a full electronic audit trail.

The reduction of manual tasks saves you at least 30% in manhours. This fact alone ensures a return on your investment in less than 1.5 years.

The SafeEx Software has a multi-purpose base, allowing a uniform setup for all units. This gives a full transparency and traceability of all units and can be used for preventive maintenance.

PCCS

The Project Completion Commissioning & Startup (PCCS) method developed ensures that the various activities within a project are done in the correct order. And, more importantly, that the next step is only taken after subsequent steps have been accepted by the responsible person. The PCCS structure also offers the possibility to record the reports and thus determine the entire process.

With the PCCS (first time right) approach, you prevent project deviations, stay within the budget and the project planning.

Turnaround Management Plan

Many companies struggle when organizing a major maintenance campaign, STOP or Turnaround. Resulting in negative effects on duration, scope completion, costs and risking short cuts due to time pressure.

The Versatec Turnaround Management Plan (TMP) is the “best practice” method for Turnaround preparation, execution with mitigation of all threats of the Turnaround process steps.

Using the TMP the Turnaround finishes in time, the scope 100% completed, executed safe and within budget.